Case Study: POSTEK RFID Solution for Retail

Project Background

Fast, affordable, stylish –These are the core strategies of fast fashion brands. These strategies target consumers between the ages 15 and 35, bringing them to the sales floor for the purchase of newly launched products every season, or monthly even. In order to reduce costs and keep pace with the ever-changing fashion trend, fast fashion brands strive to minimize inventory while rapidly developing and producing new products.

Under the brand's "fast" positioning, our customer – one of the leading international fast fashion brands – has built a comprehensive information management system, which enables products to be transferred from design to shelf in just three weeks. To provide consumers with affordable and high-quality products, a cross-national supply chain is developed and optimized with POSTEK's RFID solution.

Solution

With the rapid development of RFID technology and the growing competition among the world-leading apparel brands, our customer has accelerated its investment in digitalization, and has adopted POSTEK's RFID solution to improve and optimize its overall efficiency, budgeting control, customer satisfaction and brand awareness.

The RFID solution has been implemented throughout the supply chain, from the design and planning at the company's headquarters, to tagging and production in garment factories, shipment tracking and audition in warehouses, and finally, to cycle counting, check-out and data analysis in retail stores. A rapid turnover rate is achieved by this RFID solution – each item is tagged and tracked from manufacture to the retail stores. This enables the brand to respond quickly based on the market feedback sent from the retail stores and to arrange the according replenishment and plan adjustments.

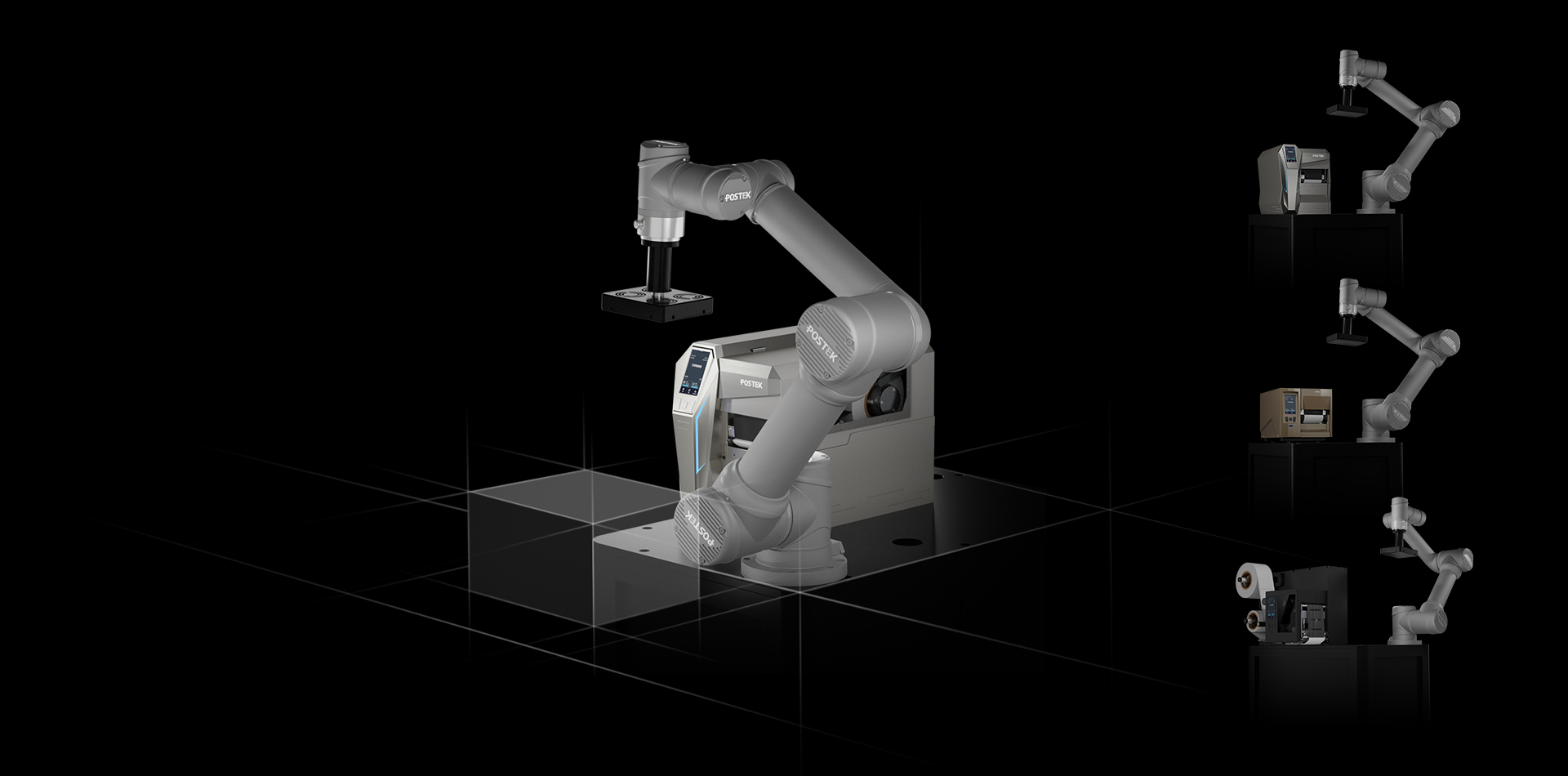

POSTEK RFID printers are mainly utilized in the IPP (In-Plant-Printing) solution in garment factories to help deliver urgent orders. Core competitiveness for the garment factories stems from efficient and stable production. Typically, a production line requires 16 hours of production per day and works in two shifts to meet the demand for fast delivery. Equipped with RFID technology, the production lines and stores can simplify this process, save time and costs, and create value for the brand by speeding up the inventory efficiency of terminal sales. It provides brands with a comprehensive understanding of their inventory in a faster and more accurate manner. This allows brands to quickly respond to the production line by supplying products with insufficient inventory, thereby improving sales performance.

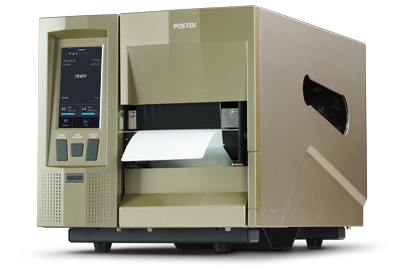

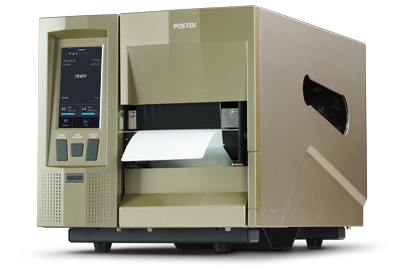

With its leading printing performance, excellent encoding capabilities and high durability, POSTEK's TXr RFID printers offer a satisfactory solution for the garment factories in Southeast Asian countries – the suppliers of the apparel brand. At the development stage, the team at POSTEK responded quickly and cooperated efficiently to deliver a tailored solution – several functions are specially designed to meet the customer's demands:

Lock parameter setting functions, including: Network settings and RFID parameter settings, effectively preventing operational mistakes during production;

Specific tag lock (R6 chip) function;

To ensure item-level tracking, unique TID data is collected from each RFID chip and then encoded into the EPC area. This way, encoded content is never repeated;

Added RFID log function, saves the TID data and encodes data into the database.

Challenges

As a fashion brand active globally, multilingual content is required on the RFID hang tags. This includes the currency, price, composition, washing instructions, and etc. Thus, the limited small-sized tag would have to contain quite a lot of printed content. The adoption of an environmentally-friendly un-coated paper has also set an even higher requirement for print quality. POSTEK’s technical accomplishments in print quality and accuracy have been fully utilized in this project. With the implementation of POSTEK's innovative heating control technology HEAT™, a high level of print quality has been achieved, even when printing intricate fonts and characters, such as those in the Korean and Traditional Chinese language. Furthermore, the heating time and energy consumption of the printhead have been reduced to a very low level, thereby extending the service life of the printhead and saving maintenance costs.

POSTEK's industrial-grade RFID printer not only meets all the functional requirements, but is also of excellent quality. It's RFID capabilities also ensure stability and accuracy in long-term non-stop mass printing and encoding processes. POSTEK's RFID printers encode and verify after printing to eliminate duplicate encoding and guarantee a 100% detection rate of faulty RFID chips, effectively preventing problems caused by unreadable RFID tags in the subsequent process flow.

Advantages

1.Enables item-level identification and tracking, and significantly improves working efficiency in cycle counting, shipment audition, check-out and the stock replenishment process;

2.Offers real-time data from the market to form a sensible, flexible and affordable system for the apparel brand for the generation of a market strategy;

3.Enhances brand awareness and improves consumer shopping experiences in the retail stores.