Project Background

Lazada, one of the largest online shopping sites in Southeast Asia, was founded in 2012. It currently has more than 70 million annual active consumers in 6 major markets including Indonesia, Malaysia, Singapore, Thailand, Vietnam, and the Philippines. Since 2016, it has become the flagship e-commerce platform of Alibaba Group, and is now the leading and fastest growing e-commerce platform in Southeast Asian market.

Fast and extensive logistics network enables Lazada to maintain its leading industry competitiveness. To guarantee efficient and accurate delivery, Lazada built its own logistics system based on Southeast Asian e-commerce infrastructure, and established its best logistics capabilities with the adoption of intelligent RFID and bar-coding solution.

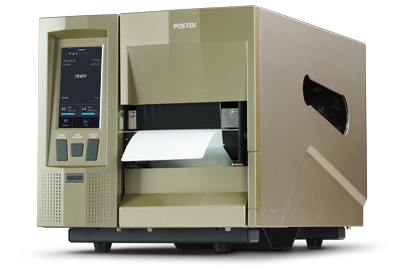

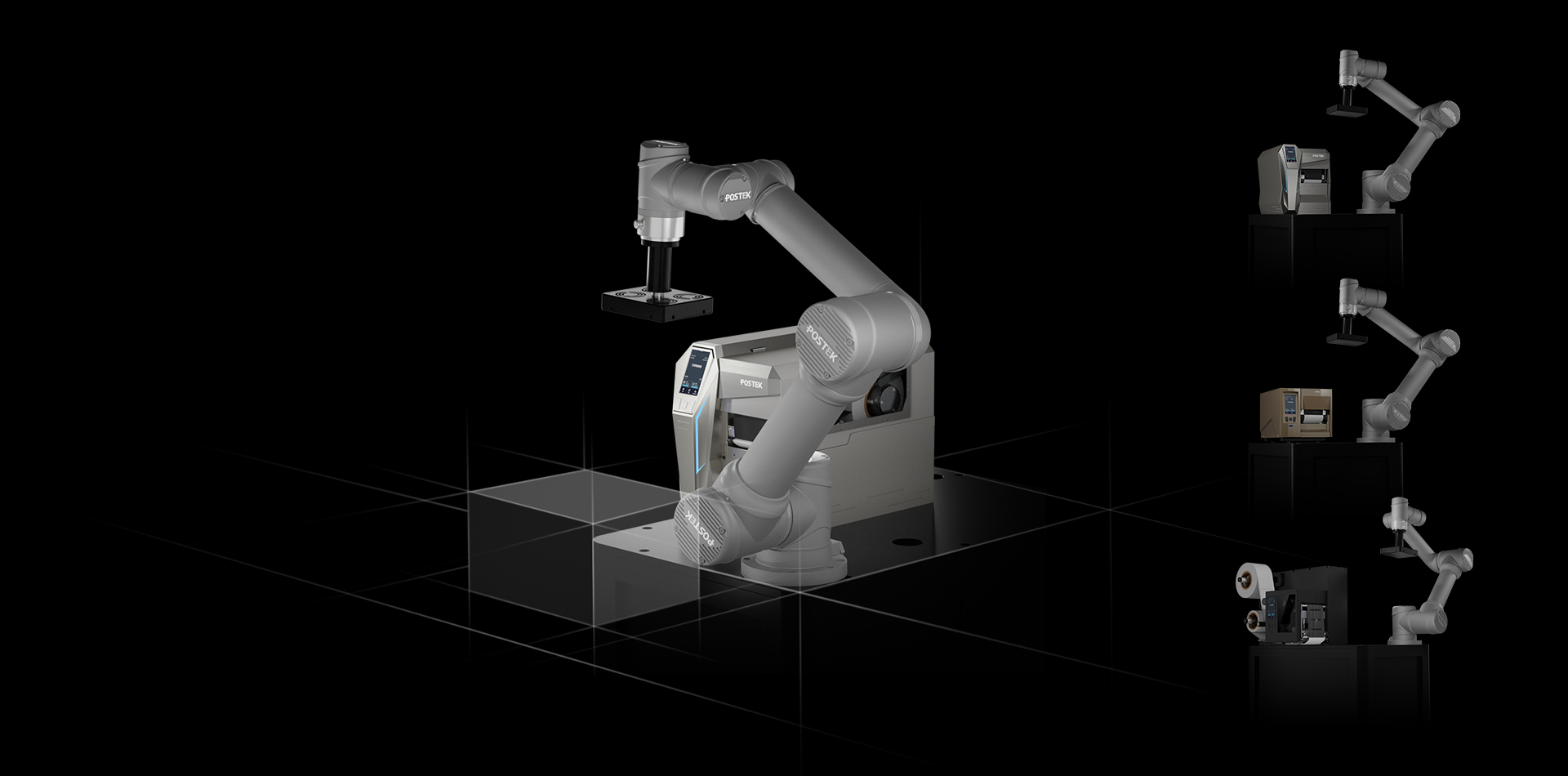

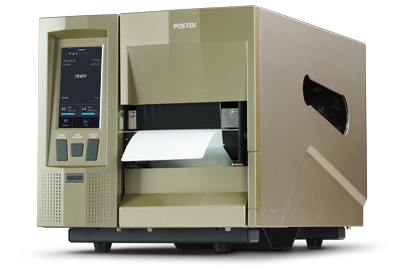

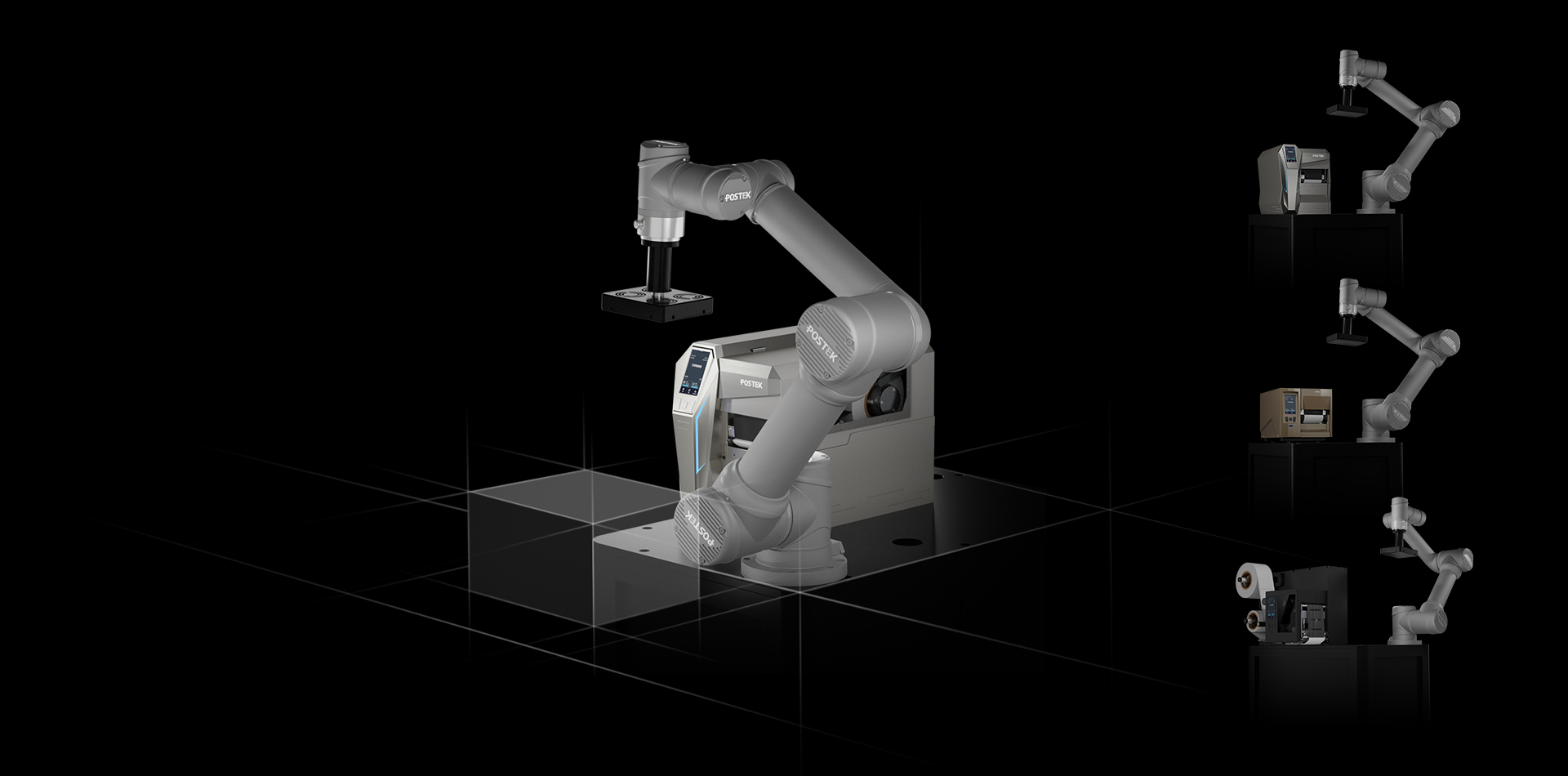

Being part of the automation logistics solution at the Lazada's global sorting centers, POSTEK provides customized RFID label's printing and encoding service. With leading RFID capabilities, easy-to-use operations and durable performance integrated in RFID printers, professional and rich experience in RFID projects, POSTEK help Lazada global sorting center to fully realize the automatic sorting system operation based on RFID and bar code technology.

Solution

Logistics sorting is one of the key links in logistics transportation, so is in Lazada's logistics system. With the adoption of automation and intelligence, Lazada, which has the largest logistics network with more than 30 storage and sorting centers in 17 cities in Southeast Asia, has realized automated operations, it can quickly and accurately complete the goods flow in warehousing, sorting and transportation through its own logistics network.

Take the first stage-Receiving and sorting at Lazada automatic sorting center as an example. Platform merchants use standardized express waybills to send goods to Lazada domestic sorting centers (in Shenzhen and Yiwu city), and the staffs will place the received goods in the sorting system. When the tagged goods are sent to a specific Read-Write area, the reader automatically collects the tag information and uploads to the sorting management system. Then the sorting management system controls the sorting gate where the goods need to be transmitted, and confirms the classification (the classified goods are concentrated in a large package). When the large package at the sorting gate is full of goods, the operator presses the gate switch to trigger the POSTEK RFID printer to automatically print an RFID label, which is attached to each large package, and the sorting work is efficiently and accurately completed. At the same time, the RFID label affixed to the large package will be the unique identification of the package in the subsequent transportation links.

Challenges

Generally, the processing time for completing the first stage of receiving and sorting (shipping from the seller's site to the domestic sorting center to complete the sorting and start transportation) will not exceed 3 days, and any mistake in sorting, printing and encoding is not allowed. With its leading RFID technologies, easy operations and strong stability, POSTEK TX3r UHF RFID printers perfectly meet the solution requirements set by Lazada's ultra-high business processing volume, strict operating regulations, and high efficiency and accuracy standards. To integrate into the operation process of the Lazada sorting management system, POSTEK provides a tailored printing and encoding solution, help realizes the simple and convenient function of automatically controlling printing and encoding through the sorting gate switch.

Besides, the extremely complicated network environment of the sorting center brings greater challenges for the stable performance of the printers. In the sorting centers, signal is always unstable, data transmission and printing interruptions often occur, which ultimately affects the accuracy and efficiency of sorting. POSTEK's technology and R&D team cooperated professionally and tacitly to develop and upgrade the printer system, optimize the printer to resume print task automatically without losing any data or wasting any RFID tags even under unstable environment.

Effects

1. Increase efficiency significantly. Goods can be sorted continuously and in large quantities in the sorting centers, not restricted by climate, time, manpower, etc.

2. Minimize the use of personnel and basically achieve unmanned operation, therefore labor cost is reduced and efficiency of personnel is greatly improved.

3. Extremely low error rate as a result of the application of RFID tags. Each package is labeled and tracked by the RFID tags, the unique TID data of every RFID tag making the package visible in the whole logistics process.